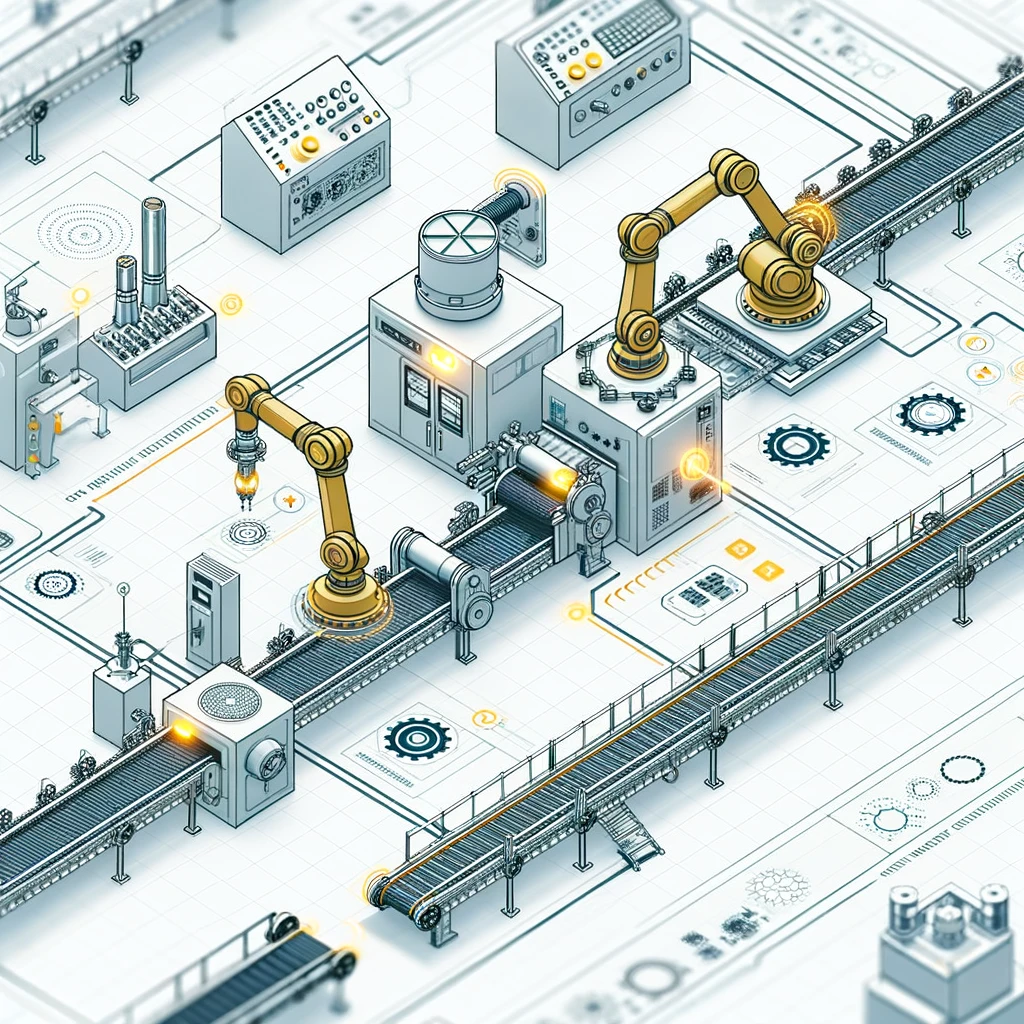

Industrial Automation is a field that involves the use of various technologies and systems to automate manufacturing and industrial processes. Through industrial automation, it’s possible to enhance efficiency, quality, and safety in production facilities. Implementing modern industrial automation systems offers several benefits, such as reducing operational costs, minimizing human errors, and improving production efficiency. This article will discuss key elements of industrial automation, including PLCs, SCADA systems, and communication protocols.

Industrial Automation: Components

Industrial automation includes various components that form an integrated system. Key elements are:

- Safety Systems: These protect workers and equipment from failures and hazardous conditions. Safety systems include emergency stop switches, gas detection systems, and light curtains.Industrial Automation: PLCs (Programmable Logic Controllers)

- Sensors and Transducers: These gather data from different industrial processes, such as temperature, pressure, liquid levels, and rotational speed. They provide critical information to control systems.

- Programmable Logic Controllers (PLCs): These act as the brain of the industrial automation system. PLCs control and monitor processes by executing programmed instructions based on sensor data.

- SCADA Systems: These systems enable monitoring, control, and data acquisition. SCADA allows operators to oversee and manage industrial processes from a central location.

- Electric Drives and Inverters: These regulate the operation of electric motors, controlling rotational speed and torque. They are essential for precise mechanical process control.

PLCs, or Programmable Logic Controllers, play a crucial role in industrial automation.

- History and Development of PLC Technology: PLCs were introduced in the early 1970s as a replacement for complex relay systems. Since then, the technology has significantly evolved, offering greater functionality and reliability.

- Basic Functions and Operation of PLCs: PLCs are programmed to perform specific tasks in response to signals from sensors. They use programming languages such as Ladder Logic and Structured Text.

- Examples of PLC Applications in Industry: PLCs are used across various sectors, including automotive, food, chemical, and energy industries. Examples include controlling production lines, packaging systems, and HVAC installations.

Industrial Automation: SCADA (Supervisory Control and Data Acquisition)

SCADA systems are essential components of modern industrial installations.

- Importance of SCADA Systems in Industry: SCADA enables remote supervision and control of processes, which is crucial for large and dispersed manufacturing facilities.

- What is SCADA?: SCADA is a computer system designed for monitoring and controlling industrial processes. It consists of user interfaces, central computers, and peripheral devices.

- How SCADA Systems Work: SCADA collects data from sensors and field devices, processes it, and presents it to operators through user-friendly visualizations. Operators use this information to make decisions and adjust processes.

- Examples of SCADA Applications in Various Industries: SCADA systems are used in energy to manage transmission networks, in chemical manufacturing to control production processes, and in water and wastewater management to monitor water distribution systems.

Industrial Automation: Communication Protocols

Communication between devices is a key element of industrial automation.

- Role and Importance of Communication Protocols: Communication protocols facilitate data exchange between different components of an industrial automation system, ensuring their cooperation and synchronization.

- Examples of Popular Protocols:

- Modbus: One of the oldest and most widely used protocols in industrial automation. It enables communication between devices over various media, such as Ethernet or RS-485.

- Profibus: Widely used in Europe, it provides fast and reliable connections between devices.

- EtherNet/IP: A modern protocol based on Ethernet technology, offering high data transmission speeds and easy integration with existing computer networks.

- Choosing the Right Protocol for an Application: The choice of protocol depends on specific application requirements, such as transmission speed, communication range, and compatibility with existing systems.

- Challenges and Issues in Communication in Industrial Automation Systems: Considerations include reliability, data security, and resistance to electromagnetic interference.

The Future of Industrial Automation

Industrial automation is rapidly evolving, introducing new technologies and solutions.

- New Technologies and Trends in Industrial Automation:

- Industry 4.0 and IoT (Internet of Things): Integration of smart devices and systems that communicate and collaborate in real time, creating more flexible and efficient production processes.

- Artificial Intelligence and Machine Learning in Industrial Automation: Utilizing AI and machine learning for process optimization, predictive maintenance, and production data analysis.

- Cybersecurity in Industrial Automation Systems: Securing systems against cyberattacks is becoming a priority in the context of increasing internet connections and remote access.

Industrial Automation: Components

Industrial automation includes various components that form an integrated system. Key elements are:

- Sensors and Transducers: These gather data from different industrial processes, such as temperature, pressure, liquid levels, and rotational speed. They provide critical information to control systems.

- Programmable Logic Controllers (PLCs): These act as the brain of the industrial automation system. PLCs control and monitor processes by executing programmed instructions based on sensor data.

- SCADA Systems: These systems enable monitoring, control, and data acquisition. SCADA allows operators to oversee and manage industrial processes from a central location.

- Electric Drives and Inverters: These regulate the operation of electric motors, controlling rotational speed and torque. They are essential for precise mechanical process control.

- Safety Systems: These protect workers and equipment from failures and hazardous conditions. Safety systems include emergency stop switches, gas detection systems, and light curtains.

Industrial Automation: Engineering Shield Services

Engineering Shield offers a comprehensive range of industrial automation services, providing integrated solutions for various industries.

- Automation System Design: We specialize in designing advanced automation systems tailored to the specific needs and requirements of our clients. Our solutions ensure optimal performance and reliability.

- PLC Programming: We provide PLC programming services, creating efficient and reliable control programs for various industrial processes. Our solutions, based on the latest PLC technologies, guarantee high quality and functionality.

- SCADA Systems: We design and implement SCADA systems that enable remote supervision and control of industrial processes. Our SCADA systems offer full visualization and real-time data management.

- Device Integration: We ensure comprehensive integration of various devices and systems into a single, cohesive automation system. This makes our solutions more efficient and easier to manage.

- Production Line Concepts: We offer design and optimization services for production lines, tailored to the specific needs of the client. Our solutions ensure maximum productivity and efficiency.

- Machine Safety: We design and implement machine safety systems to protect workers and equipment from failures and hazardous situations. Our solutions meet the highest safety standards.

- Compliance with Essential and Minimum Requirements: We assist our clients in adapting machines and equipment to legal requirements and safety standards. Our services include audits, risk analyses, and implementation of necessary changes.

Industrial Automation and the Machinery Directive

Industrial automation plays a crucial role in meeting the requirements of the Machinery Directive, which aims to ensure a high level of safety for machines and equipment used in industry. The Machinery Directive (2006/42/EC) specifies the essential and minimum requirements that machines must meet to be marketed in the European Union. In the context of industrial automation, it is vital that automation systems are designed and implemented in accordance with these requirements. This includes incorporating appropriate safeguards, emergency stop systems, and maintenance procedures.

Industrial automation enables the implementation of advanced monitoring and control systems that ensure not only operational efficiency but also machine safety. PLC and SCADA systems can be configured to monitor critical operational parameters and immediately respond to any deviations from norms, minimizing the risk of accidents. Additionally, the integration of communication protocols allows for seamless connection between various system components, which is crucial for maintaining compliance with the Machinery Directive.

Adapting machines to the Machinery Directive’s requirements often involves audits and risk analyses that identify potential hazards and determine preventive measures. Industrial automation supports these processes by providing tools for precise monitoring of machine conditions and documenting all maintenance and safety-related activities. As a result, companies can not only meet legal requirements but also enhance overall efficiency and reliability in their production operations.

Implementing industrial automation in compliance with the Machinery Directive not only raises safety standards but also contributes to better process management, reduced downtime, and optimized operational costs. It is a crucial step towards a sustainable and safe industry that meets the highest European quality and safety standards.

Harmonized Standards with the Machinery Directive, LVD, and EMC

| Standard | Description | Directive |

|---|---|---|

| EN ISO 12100 | Machinery safety – General principles for design – Risk assessment and risk reduction | Machinery Directive |

| EN 60204-1 | Safety of machinery – Electrical equipment of machines – Part 1: General requirements | Machinery Directive |

| EN ISO 13849-1 | Machinery safety – Safety-related parts of control systems – Part 1: General principles for design | Machinery Directive |

| EN ISO 13850 | Machinery safety – Emergency stop function – Principles for design | Machinery Directive |

| EN 62061 | Functional safety of electrical, electronic and programmable electronic safety-related systems | Machinery Directive |

| EN 60947-1 | Low-voltage switchgear and controlgear – Part 1: General rules | LVD Directive |

| EN 61508 | Functional safety of electrical/electronic/programmable electronic safety-related systems | LVD, EMC Directive |

| EN 61000-6-2 | Electromagnetic compatibility (EMC) – Part 6-2: Immunity for industrial environments | EMC Directive |

| EN 61000-6-4 | Electromagnetic compatibility (EMC) – Part 6-4: Emission requirements for industrial environments | EMC Directive |

| EN 61326-1 | Electrical equipment for measurement, control and laboratory use – EMC requirements – Part 1: General requirements | EMC Directive |

| EN 60950-1 | Information technology equipment – Safety – Part 1: General requirements | LVD Directive |

| EN 61131-2 | Programmable controllers – Part 2: Equipment requirements | LVD, EMC Directive |

Diretives description

Machinery Directive (2006/42/EC): Defines the requirements for the design and construction of machinery to ensure safety and protection of users’ health. It applies to all machinery placed on the European market.

LVD (Low Voltage Directive) 2014/35/EU: Covers electrical equipment operating within specified voltage ranges. It ensures electrical safety by addressing aspects such as insulation, protection against electric shock, and resistance to voltage surges.

EMC (Electromagnetic Compatibility) Directive 2014/30/EU: Addresses the electromagnetic compatibility of equipment, ensuring that devices do not cause electromagnetic interference and are resistant to disturbances from other sources.

Summary

Industrial automation is a crucial component of modern industry, enabling increased efficiency, quality, and safety in production processes. Implementing modern technologies such as PLCs, SCADA systems, and advanced communication protocols leads to improved outcomes and market adaptability. The future of industrial automation is tied to the ongoing development of Industry 4.0 technologies, artificial intelligence, and cybersecurity, which present new opportunities and challenges for the industry.

FAQ: Industrial automation

Industrial automation is a field of engineering focused on the design and implementation of control and monitoring systems for industrial processes. Its goal is to enhance efficiency, safety, and quality of production through the automation of operations.

The main components of industrial automation systems include sensors and transducers, programmable logic controllers (PLC), SCADA systems, electric drives and inverters, and safety systems.

A PLC (Programmable Logic Controller) is a specialized computer used for automating industrial processes such as controlling machines and production lines. PLCs can be programmed to perform various tasks based on signals from sensors and field devices.

A SCADA (Supervisory Control and Data Acquisition) system allows for remote supervision and control of industrial processes by collecting, processing, and visualizing data from sensors and field devices. It enables operators to monitor and manage processes in real-time.

The most popular communication protocols in industrial automation are Modbus, Profibus, and EtherNet/IP. Each of these protocols has its specific applications and advantages depending on the requirements of the system.

The Machinery Directive (2006/42/EC) is a European regulation that specifies safety and health requirements for machinery placed on the European market. The aim of the directive is to ensure that machinery is safe for users and meets specified standards.

Industrial automation supports compliance with the Machinery Directive by implementing advanced monitoring and control systems that ensure machine safety, risk reduction, and legal compliance.

Engineering Shield provides services in designing automation systems, programming PLCs, SCADA systems, device integration, production line concepts, machine safety, and adapting machines to essential and minimum requirements.

The LVD (Low Voltage Directive) 2014/35/EU pertains to electrical equipment operating within specified voltage ranges. Its aim is to ensure electrical safety by addressing aspects such as insulation, protection against electric shock, and resistance to surges.

The EMC (Electromagnetic Compatibility) Directive 2014/30/EU addresses the electromagnetic compatibility of equipment. It is important in industrial automation because it ensures that equipment does not cause electromagnetic interference and is resistant to disturbances from other sources, which is crucial for the reliable and safe operation of automation systems.

See also: