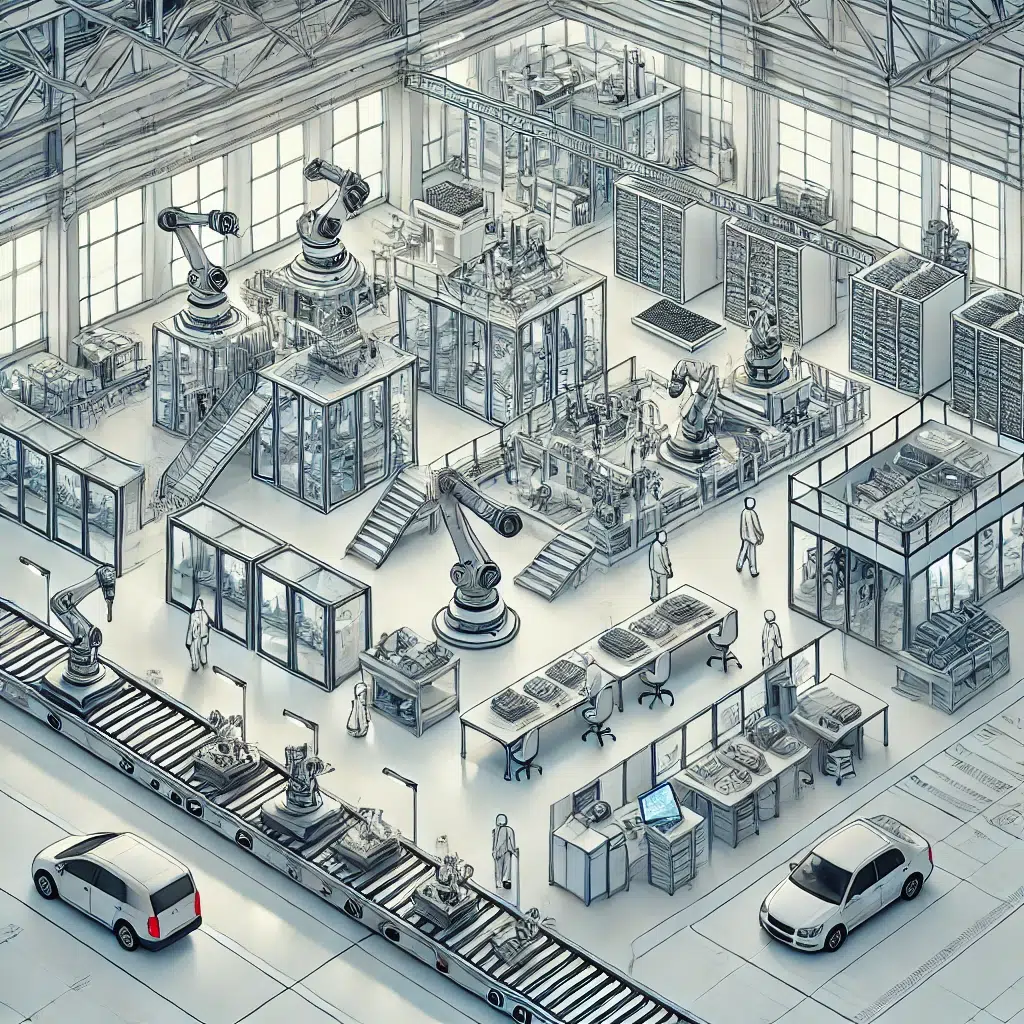

Special machinery plays a pivotal role in modern industry, especially when standard solutions fail to meet specific production requirements. The term “special machinery” refers to custom-designed equipment precisely tailored to the unique needs of a particular production process. Unlike standard machines, which can be applied across various applications, special machinery is unique and crafted to accomplish tasks that demand non-standard technological solutions.

In the automotive industry, special machinery is indispensable. Every new car model necessitates adjustments to the production line, often requiring the design of new machines for processes such as assembly, welding, gluing, soldering, or painting. While these processes are similar across different models, each new part or function may require individually designed equipment, highlighting the flexibility and versatility of special machinery in this sector.

In the pharmaceutical industry, the requirements for special machinery vary depending on the type of production. In mass production, where the priority is continuous and efficient production of large quantities of drugs, high-performance and precision machines are crucial. Conversely, in batch production, where products are manufactured in smaller batches, flexibility becomes a key factor. Special machinery must quickly adapt to different production configurations, enabling smooth batch changes and minimizing downtime. This flexibility dictates the need for “special” solutions in pharmaceuticals, where product diversity and rapid change are the norm.

In situations where standard technologies are insufficient, developing new technological solutions becomes necessary. This process involves greater risk, as the final outcome is not predetermined. In such cases, designing special machinery often requires research and development efforts and the application of flexible project management methods, such as the AGILE approach, which allows for quick response to changing needs and technological challenges.

Table of Contents

Standard Production Processes and Special Machinery in Various Industries

Every industrial sector has its unique requirements that determine the type of machinery used and the specifics of production processes. Standard machines and production lines are typically designed for maximum efficiency and process repeatability, which is effective in mass production. However, in situations where flexible approaches are needed, such as in batch production, the importance of special machinery, tailored to specific production needs, increases.

Automotive Industry

In the automotive industry, standard production processes include operations such as assembly, welding, gluing, soldering, painting, stamping, and transportation. Each new car model requires appropriate adjustments to the production line, often involving the creation or modification of machines dedicated to specific operations. Although basic processes are generally similar, each new generation of vehicles introduces innovations that may require new production technologies. An example is the production of lightweight body structures, which requires advanced welding and gluing technologies for new materials like aluminum or composites.

Pharmaceutical Industry

In the pharmaceutical industry, standard production processes include mixing ingredients, dosing, filling, packaging, and quality control. In mass production, continuity and efficiency are crucial, requiring precisely designed high-performance machines. In batch production, where products are manufactured in smaller batches, machine flexibility becomes a key factor. Machines must quickly switch between different production configurations, allowing rapid production line changes and minimizing downtime. This kind of flexibility is particularly important in pharmaceutical production, where the diversity of products, such as different forms of drugs (tablets, capsules, liquids), requires various production settings.

Other Industries

In other sectors, such as the food or chemical industry, standard production machines often include packaging lines, dosing systems, and robotic palletizing and “pick and place” stations. In food production, where high hygiene standards must be maintained, machines must be easy to clean and corrosion-resistant. In the chemical industry, machines must be adapted to work with various, often aggressive chemicals, imposing high material and technological requirements.

Standard processes and machines are integral to efficient production, but in situations requiring greater flexibility or the implementation of new technologies, special solutions become crucial. These machines are designed with the specific requirements of a given industry in mind, allowing for process optimization and better adaptation to changing market needs.

Special Machinery: Designing and Implementing New Technologies

Designing special machinery presents unique challenges, especially when it requires creating entirely new technological solutions. While standard machines are based on proven technologies and processes, special machinery often needs to be adapted to entirely new production requirements, introducing an element of uncertainty and risk.

Research and Development

One of the main challenges in designing special machinery is the need for research and development (R&D) efforts aimed at developing new technologies or significantly modifying existing processes. In such cases, designers and engineers often operate at the edge of current knowledge and technology, meaning the final project outcome is not predetermined. This process can be lengthy and costly, but it is essential to meet specific customer requirements and ensure market competitiveness.

AGILE Approach in Design

In the face of these challenges, the AGILE approach is gaining popularity, allowing for flexible management of special machinery projects. This methodology, inherently iterative and adaptive, enables quick responses to changing conditions and needs. In projects where technology must be developed, AGILE allows for gradual innovation and real-time solution testing, helping to minimize risk and control costs. This enables project teams to quickly identify and resolve issues, which is crucial in situations where there is no clear vision of the final product.

High Risk and Uncertainty

Introducing new technology in special machinery involves a high level of risk. This stems from uncertainty about the effectiveness of new solutions and the possibility of encountering unforeseen problems during testing and implementation. In such projects, close collaboration between engineering, research teams, and the client is essential to continually adapt solutions to current needs and challenges. High risk also means these projects often require larger budgets and time for completion, which can be challenging for both suppliers and recipients of these technologies.

Specialization vs. Flexibility

Another challenge is balancing specialization and flexibility in machines. While some special machines are designed for very specific tasks, allowing for maximum efficiency, others must be flexible enough to adapt to different production processes or be easily modified. This kind of flexibility is particularly important in industries such as pharmaceuticals, automotive, or FMCG, where production processes often need to be adapted to different types of products and production standards.

In summary, designing special machinery requires not only advanced technical knowledge but also the ability to manage risk and innovative projects. It also requires close collaboration between different teams and a flexible approach to changing needs and technological challenges.

The Process of Designing Special Machinery

Designing special machinery is a complex process that requires a thorough understanding of the client’s specific needs, precise development of technical specifications, and going through several key stages, such as concept creation and mock-ups. Each of these steps is necessary to ensure that the final product not only meets but also exceeds expectations in terms of functionality, performance, and reliability.

Client Needs Analysis

The process of designing special machinery always begins with a detailed analysis of the client’s needs. This stage is crucial as it forms the foundation for all subsequent design activities. Engineers and designers must closely collaborate with the client to understand specific production requirements, spatial constraints, industry standards, and any other factors that may influence the final shape of the machine. This often requires not only discussions with the client but also an analysis of existing production processes to identify areas where improvements or innovations can be introduced.

Technical Specification

After understanding the client’s needs, the next step is developing the technical specification. This specification is a detailed document containing all technical requirements for the designed machine. It includes mechanical, electrical, ergonomic parameters, as well as any standards and regulations that must be met. Precisely defining these requirements early in the design process is crucial as it helps avoid errors and misunderstandings in later project phases. A well-prepared technical specification serves as a reference point for the entire project team, ensuring consistency and alignment with the client’s expectations.

Concept Creation and Preliminary Design

Once the technical specification is established, engineers proceed to create the machine concept. At this stage, designers consider various possible technical solutions that can meet the defined requirements. Sketches and preliminary models are created to visualize potential solutions. Often, several different concepts are developed, which are then discussed with the client to select the most suitable solution.

These concepts are evaluated for feasibility, cost, performance, and the ability to meet all specification requirements. At this stage, preliminary computer simulations may also be conducted to assess how the designed machine will function in practice. The final concept choice results from a compromise between the optimal technical solution and budgetary and time constraints.

Special Machinery: Mock-up and Prototyping

The next crucial stage is creating a mock-up, a demonstration model that reflects the main features and functionalities of the designed machine. The mock-up can be physical or virtual (in 3D), depending on the project’s complexity and available resources. Its main purpose is to visualize and verify the selected concept before proceeding to build a full-scale prototype.

The mock-up allows the client to thoroughly familiarize themselves with the future machine and provide feedback or suggestions. At this stage, changes can still be made, allowing for better project alignment with expectations. Additionally, mock-ups help identify potential technical problems that can be resolved before full production begins.

For more advanced projects, after the mock-up, the prototyping phase follows, where a fully functional machine prototype is built. The prototype is tested under conditions close to real ones, allowing for final confirmation that the machine meets all requirements and is ready for implementation on production lines.

FAQ: Special Machinery

Special machinery refers to custom-designed equipment tailored to the unique needs of a specific production process. Unlike standard machines, which are mass-produced and can be used in various applications, special machinery is unique and serves to accomplish specific production tasks requiring non-standard technological solutions.

Designing special machinery involves several key stages: analyzing client needs, developing technical specifications, creating concepts and preliminary designs, and creating mock-ups and prototypes. Each of these stages is essential to ensure that the final product meets all client requirements and operates efficiently in the production process.

Special machinery is used in many industries, including automotive, pharmaceutical, food, chemical, and electronics. In each of these sectors, these machines are used to carry out production processes that require precise, tailored solutions to specific needs.

Designing special machinery often involves a high level of risk and uncertainty, especially when new technologies need to be developed. These challenges include the need for research and development, risk management, and ensuring machine flexibility to adapt to changing production needs.

Special machinery offers numerous benefits, such as increased production efficiency, reduced operational costs, improved quality and repeatability of processes, and the ability to perform complex production tasks that would not be possible with standard machines. These advantages allow companies to better tailor their production processes to specific market requirements.