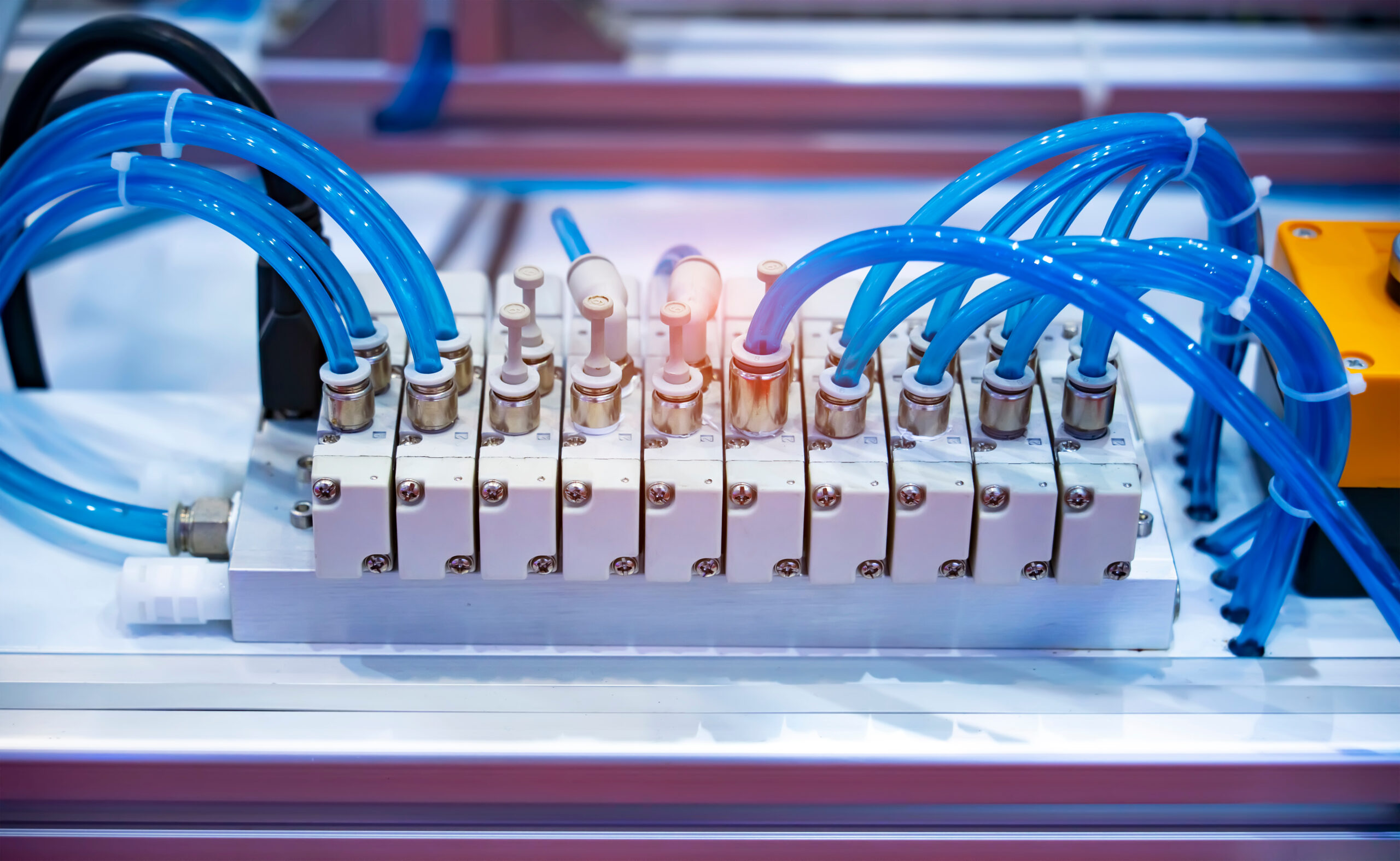

Modern machinery and production lines extensively utilize pneumatic systems for drive and control. Pneumatics is ubiquitous in industries—from automotive feeders and actuators to electronics manipulators and FMCG packaging machines. Compressed air enables rapid movements and high forces with relatively simple construction. However, the same compressed air poses hidden dangers: it stores energy under pressure, can cause uncontrolled movements of actuators, and accidents if the system is not designed safely. The PN-EN ISO 4414 standard outlines general principles and safety requirements for pneumatic systems on machines. It provides a framework for designing in compliance with the Machinery Directive 2006/42/EC and offers guidance on avoiding common hazards. Below are 10 key tips for engineers to help design pneumatic systems in line with PN-EN ISO 4414, ensuring reliability and safety for both people and production processes.

Table of Contents

1. Familiarize Yourself with EN ISO 4414 and Safe Pneumatics Basics

The first step for any designer should be to thoroughly understand PN-EN ISO 4414 and the general principles of machine safety. The PN-EN ISO 4414:2011 standard (titled “Pneumatic fluid power—General rules and safety requirements for systems and their components”) is harmonized with the Machinery Directive. This means that adhering to its guidelines facilitates compliance with legal requirements when CE marking a machine. The standard describes potential hazards associated with pneumatics (e.g., energy accumulation of compressed air, sudden actuator movements, control element failures) and provides ways to eliminate or reduce them. For engineers, understanding these hazards and safety mechanisms is crucial. Familiarity with the standard and related standards (e.g., PN-EN ISO 12100 concerning general risk assessment principles) provides a solid theoretical foundation. Basic knowledge of safe pneumatics—how safety valves work, what a safe system state is, what typical failures are—allows for conscious application of further tips and avoids design errors that threaten user life or health.

2. Conduct a Risk Analysis and Define Safety Requirements (ISO 12100, ISO 13849)

Safe pneumatic design always starts with a risk analysis. According to PN-EN ISO 12100, before designing a system, identify possible hazards and assess the risk associated with each element and situation. Analyze each actuator, valve, and machine movement: Are there dangerous points (e.g., finger pinch points)? Could an element’s movement strike someone? Could a failure result in a sudden release of elements or air expansion? Ask questions about failure consequences: what happens if a hose breaks, a valve jams, or power is lost? Such analysis indicates which system functions must have a safety character.

Once you know the hazards, define the required safety functions for the pneumatic system. This is where PN-EN ISO 13849-1 comes into play, addressing the safety of control systems (including pneumatic ones) and determining their ability to reliably perform safety functions. Based on the risk analysis, decide what Performance Level (PL) is needed for each function. The more severe the hazard (severe injuries) and the more frequent the risk exposure, the higher the level of protection required. For simple, less dangerous hazards, a basic level (PL a or b) suffices, but for critical ones—e.g., stopping a press or manipulator when a guard is opened—the highest level (PL d or e) may be required. This translates into the safety category architecture of the system (from B, 1, 2 to 3 or 4 according to ISO 13849). In practice, this means that key pneumatic circuits may require redundancy and diagnostics (see tip 4) to meet, for example, category 3 or 4. Consider these requirements already at the design stage—it’s easier to build a safe system from scratch than to retrofit an existing machine for safety. Also, document the findings from the risk analysis—it will be useful during audits and certification (more on this later).

3. Prevent Uncontrolled Movement and Sudden Machine Start

One of the most common and dangerous hazards in pneumatic systems is unexpected actuator movement or sudden machine start. This can occur, for example, when air supply is reconnected after a stop, when pressure drops, or due to control system malfunctions. PN-EN ISO 4414 emphasizes protection against unintended start-up—the machine must not start on its own until deliberate control actions are taken. How to achieve this in practice?

Use safety valves to prevent sudden start. Special progressive start valves (so-called soft-start valves) gradually supply pressure to the system after activation, gradually starting the actuators. This prevents a sudden actuator jump to a random position when the operator is unprepared. Another solution is cut-off valves with control—until the control system signals readiness, such valves block air supply to the actuators. They can be integrated with electrical systems (e.g., coupled with guard opening or restart button).

Detect pressure drops and power failures. Installing pressure sensors or pneumatic switches that detect sudden pressure loss in the system is a good idea. A sudden pressure drop may indicate a failure (e.g., a broken hose)—such a sensor can then block automatic machine restart until the operator checks and resets the system. Modern machines also use safety PLCs monitoring valve and pressure states—ensuring that movement occurs only after safety conditions are met upon power restoration.

Design the system with predictable start-up in mind. This means, for example, designing actuators to be in a safe state (retracted or extended depending on the application) in the starting position and ensuring controlled return to the working position. Additionally, eliminate situations where compressed air could spontaneously drive movement: e.g., a heavy arm may fall under its weight, sucking air through a valve—use mechanical supports or brakes (discussed in subsequent points). Remember that a worker performing maintenance or troubleshooting may be in the machine area—no axis should move unexpectedly just because pressure is restored. Proper protection against uncontrolled movement is the foundation of safe pneumatics.

4. Use Redundancy and Reliable Components in Critical Circuits

Redundancy is the principle of duplicating key elements so that the failure of one does not result in the loss of safety function. In industrial pneumatics, this often means using double valves in circuits responsible for stopping or cutting off air supply. For example, in an emergency unloading system (air cutoff), instead of a single 3/2 solenoid valve cutting off air supply, two valves are installed in series, controlled and monitored simultaneously. If one valve fails or jams open, the other still cuts off the air supply—the machine enters a safe state. Such a double system, often called dual-channel, is required to achieve high safety categories (cat. 3 or 4 according to ISO 13849) and high PL. Monitoring both valves (e.g., position sensors of their spools or pressure sensors behind each) allows detection if one does not close properly—then the system reports an error and does not allow normal start until the fault is resolved. These types of redundant safety modules are commonly used in industrial presses or automotive assembly lines, where the highest level of protection against unintended movement is required.

Besides cutoff valves, consider redundancy in other critical elements: if you have an important pressure sensor ensuring safe operation—you can use two sensors and compare their readings. When using throttle valves to limit speed in safety functions, ensure they are proven design elements (preferably with certification or documented B10d/MTTFd). Component reliability is as important as redundancy. Use elements from reputable suppliers, designed for safety applications or with so-called well-tried engineering practice. For example, special safety valves for pneumatics have reliability data from long-term tests—choosing such a valve ensures it will withstand millions of cycles without failure. ISO 13849 documentation provides parameters like B10d (number of cycles to 10% dangerous failures)—use them when selecting components.

Do not skimp on quality: a cheaper, uncertain element can undermine the entire meticulous safety plan. Imagine the only air cutoff valve fails and remains open—if there is no second one in reserve, the machine will not stop when it should. Therefore, in all circuits whose operation is critical to safety (e.g., power cutoff, load holding, emergency braking), apply the principle of “twice as sure”: two elements instead of one, plus state control. This approach significantly increases system reliability. Let’s add that redundancy also applies to, for example, two-hand control systems—in older pneumatic systems, two pneumatic buttons were used simultaneously by both operator’s hands, ensuring they did not insert a hand into the danger zone. In modern systems, this is done electrically, but the principle is the same: two channels to exclude accidental activation with one hand or one button failure.

In summary: design critical circuits as if assuming the failure of each single element—add a second protective element and choose the highest quality components. Such engineering foresight reflects the spirit of PN-EN ISO 4414 and significantly enhances machine safety.

5. Design the Pneumatic System with the Fail-Safe Principle (Failure Resistance)

Fail-safe is a fundamental principle of safe design: the system should be designed so that in case of any failure, it enters a safe state or at least does not pose an additional hazard. In the context of pneumatics, this means that power loss, hose rupture, or valve failure should not cause uncontrolled, dangerous machine behavior.

How to achieve fail-safe in pneumatics? Here are some practical tips:

- Valves with safe neutral position: Use directional valves that, in the resting position (e.g., without power), set themselves in a safe configuration. For example, a 5/2 valve controlling an actuator may block flow or open the actuator to the atmosphere in the unpowered state, so the actuator does not move or falls without force. NO/NC (normally open/closed) valves in appropriate places can cut off or release air when control is lost. Determine which option is safe for a given axis: sometimes it’s better for the actuator to retract (e.g., to move away from danger), and sometimes the opposite—to extend and block another part’s movement. Choose valve logic so that electrical or pneumatic power failure leads to the safest possible position of all elements.

- Mechanical locks and brakes: In some situations, especially when pneumatics support heavy loads or work vertically, pressureless “descent” of the actuator can be dangerous (e.g., an arm falls under its weight). Then mechanical safeguards are necessary. A popular solution is pilot-operated check valves (so-called load-holding valves) mounted on the actuator—they maintain pressure in the actuator during power loss, preventing the piston from falling. Another option is a brake or lock on the actuator rod/shaft, which automatically clamps when pressure is lost (a spring forces movement lock). For example, in the automotive industry, cylinders with built-in stopping brakes are used to prevent the body from falling on a lift during a power failure. Ensure that every potentially uncontrolled descent or movement is blocked by the system’s design.

- Protection against hose rupture: A broken compressed air hose is not only a loss of pressure but also a risk of “whipping” the hose end under pressure and immediate actuator descent. To prevent this, special flow safety valves, sometimes called anti-whip or flow fuses, can be used. They are installed on the supply lines to the actuator—if the air flow suddenly exceeds the normal level (indicating leakage and air escape), such a valve closes automatically, limiting the outflow. This way, the actuator descends more slowly, and the hose does not “whip” as dangerously. Consider these elements in critical places, e.g., with large cylinders or where hoses are prone to damage.

- Controlled braking of movement: In an emergency, quick movement stopping is important, but equally important is avoiding damage from too abrupt braking (e.g., mechanical damage). Quick exhaust valves can be used near actuators to immediately release air and dissipate movement energy—this ensures a quick stop. Sometimes they are combined with throttles so that braking is fast but not jerky. In applications with very high inertia (e.g., machines in the wood or steel industry), valves alone may not suffice—energy absorbers (hydraulic dampers) are added to gently brake the piston movement in the final phase. It is important to anticipate how to stop movement in an emergency without an accident and without machine destruction already at the design stage.

In summary, fail-safe design is the art of anticipating failures: think about what will happen “if…” and design the system so that even in that scenario, no one gets hurt, and damage is minimal. PN-EN ISO 4414 lists various measures—from purely pneumatic solutions (valves, vents) to mechanical (locks)—that together provide failure resistance. Use these measures as needed. Even if certain elements added for safety increase cost or complicate the system, remember that it’s about human life and health and equipment protection. A well-designed pneumatic system “forgives” a single failure without tragedy—that’s the idea of fail-safe in practice.

6. Ensure Safe Power Cutoff and Venting Before Maintenance (LOTO Principles)

Every machine with a pneumatic system must have means for safely disconnecting the air supply and releasing pressure before starting maintenance work. The energy stored in compressed air can cause serious harm if not released—imagine a mechanic unscrewing a hose still under 6 bar pressure! Therefore, when designing the system, be sure to provide a cutoff and venting point (Lockout/Tagout).

Install a manual cutoff valve with a locking option (LOTO). Ideally, place a ball cutoff valve or similar valve right at the air supply entrance to the machine, isolating the entire pneumatic system from the main compressed air network. Such a valve should have the ability to lock with a padlock in the closed position—so the person performing maintenance can close and lock it with a padlock (often with a warning tag, hence the Lockout/Tagout procedure). Many safety standards and regulations (e.g., American OSHA) even require such solutions. During a safety audit, it is checked whether the operator has easy access to disconnecting the pneumatics supply and whether it can be secured against accidental activation by bystanders.

Ensure automatic venting of residual pressure. Simply cutting off the compressed air supply is not enough—air may still be trapped under pressure in hoses and actuators. When designing, add a venting valve (often integrated with the main valve or as a separate three-way valve type 3/2). After closing the supply, it directs internal pressure outside (to the atmosphere), allowing quick and safe energy discharge. Make sure this air is vented safely—in a place where no one is hit by the air stream or airborne particles. Noise mufflers are often used on such a valve’s exhaust to prevent loud hissing from startling people and damaging hearing.

Procedures and markings: Already at the design stage, think about the convenience and clarity of the LOTO procedure. The cutoff valve should be clearly marked (e.g., with a red/yellow handle, “Air cutoff valve—close before work” sign). A good practice is to design the possibility of closing the system in a pressureless position and checking this state. For example, provide pressure gauges or indicators on the main branch—so the maintenance technician can see if the pressure has indeed dropped to zero after venting.

Protection against reactivation: The whole point of LOTO is to avoid the situation where someone accidentally turns on the machine while another person is working on it. Therefore, a valve with a padlock is necessary, but additionally, the design may include a position sensor of this valve connected to the control system—so that the machine cannot be started electrically when the valve is closed (this is optional but a solution that increases safety).

Remember that compliance with PN-EN ISO 4414 will also be assessed in terms of these elements. During certification, it is necessary to check whether the machine has an easily accessible, properly functioning, and described pneumatic energy cutoff system. Lack of such a system is a direct path to failing the audit. Moreover, it poses a real life threat to maintenance personnel. Always include a safe cutoff and venting module in the design—it’s a small cost and simplicity of operation, yet it saves health and meets legal requirements.

7. Limit Speeds and Forces—Safe Regulation of Pneumatic Movement

Pneumatic systems can generate very high forces and speeds. Many applications are tempted to use maximum capabilities—a fast piston stroke increases efficiency, and high pressing force ensures certain operations. However, from a safety (and machine durability) perspective, it is often better to limit speed and force to the required level but not excessively exceeding the needs. PN-EN ISO 4414 indicates that controlling system operating parameters is crucial for avoiding mechanical hazards.

Use flow regulation (throttling) to control speed. Each actuator should have throttle-check valves or flow regulators installed, allowing to set the appropriate extension and retraction speed. Set these speeds as low as possible without losing process functionality. Too fast movement not only increases accident risk (because it’s harder to escape from a quickly approaching element) but also causes mechanical shocks, greater component wear, and noisier operation. For example, in the electronics industry, where manipulators handle delicate elements, pneumatics is often throttled to smooth, gentle movements—minimizing the risk of component damage and potential hazard to personnel.

Reduce supply pressure for smaller forces where full power is not needed. Not every actuator in a machine needs to operate at maximum pressure of 6–8 bar. Often the application requires only a fraction of this force. Pressure reducers provided in the system for individual circuits allow adjusting the actuator’s force to the task requirements. By reducing pressure, you reduce pressing force—thus, the potential impact or crushing effect is less dangerous. For example, if an actuator only moves a light product on a conveyor, set it to 3 bar instead of 7—in case of contact with a person, the force will be significantly lower. An additional benefit is energy savings and less compressor wear.

Add soft start and stop functions. The previously mentioned soft-start valves not only prevent sudden jumps during startup but can also act as initial speed limiters. Similarly, using pneumatic or hydraulic dampers at the ends of actuator movement ensures it brakes without impact. Most actuators have built-in end-of-stroke damping—always enable and adjust it. If not, add external dampers. Safe braking protects against debris or mechanism breakage in case of collision.

It is also worth noting that in an emergency, lower speed means easier movement stopping. A cutoff valve will cut off the air, but a moving piston will still travel a certain distance—the slower it was going, the shorter the overrun distance. Lower force, in turn, means less kinetic energy to dissipate. Thus, limiting these parameters daily makes the machine safer even in emergencies.

Example from practice: in the packaging industry (FMCG), machines often work at enormous packaging speeds. However, when the operator opens a guard in setup mode, the machine switches to slow motion mode—pneumatics operates with reduced pressure and throttling, allowing the operator to safely observe movements and not be hit by a fast-moving actuator. This shows the philosophy: give full speed only where and when it is safe. During the design phase, ensure you have the ability for such regulation and do not exceed reasonable values. Remember—a safe machine is not always the fastest machine, but certainly one that avoids unnecessary risk.

8. Consider Machinery Directive Requirements and Prepare for Certification Audit

Designing a pneumatic system according to the above tips effectively implements the requirements of the Machinery Directive 2006/42/EC and related standards. This is important because every machine introduced to the market (in the EU) must meet essential safety and health requirements specified in the Directive, and the manufacturer must demonstrate this in the technical documentation. Using harmonized standards, such as PN-EN ISO 4414 or PN-EN ISO 13849, provides a presumption of conformity with these requirements—in other words, if your solutions comply with the standards, it is assumed that you meet the relevant directive requirements.

Preparation for audit/certification should occur concurrently with design. This means documenting design decisions related to safety, recording risk analysis results, creating pneumatic circuit diagrams with marked safety elements. When it comes time to evaluate the machine (whether internal or by an external auditor or notified body), you will have a complete set of information. The auditor will certainly ask: does the machine have appropriate means to prevent sudden start? Does it have an energy cutoff system? Do safety functions have the required reliability level? By applying the standards earlier, you will be able to answer these questions affirmatively and support them with specific solutions.

Compliance with PN-EN ISO 4414 also matters internationally. If you create a machine that will go to other countries, local safety inspectors or recipients (e.g., large corporations) may require proof that recognized safety standards have been applied. For example, automotive factories worldwide often require that delivered equipment has safety solutions compliant with ISO standards and internal corporate standards. Referring to “design compliant with PN-EN ISO 4414” in documentation adds credibility. Also, during technical acceptance of the machine at the client’s site, details such as the presence of a LOTO valve, safety sensors, redundant valves, etc., are checked—all of which were discussed in previous points.

Avoid costly corrections and delays. If you ignore safety requirements in the design, there is a high risk that non-conformities will be detected during acceptance or certification. The need for last-minute modifications (e.g., adding valves, guards, locks) is very costly and may delay line start-up. In the worst case, the machine may not obtain CE certification, preventing its legal use. Therefore, design “for audit” from the very beginning: each of these 10 tips simultaneously increases safety and brings you closer to a positive compliance assessment.

An important element is also complete documentation: diagrams, descriptions of safety function operation, a list of standards applied. Present this set during the audit—it shows that you consciously designed the system according to requirements. Auditors trust projects supported by analyses and references to standards much more than those where “something is installed because it turned out that way.” So take advantage of the fact that PN-EN ISO 4414 is clearly formulated—you can even make a checklist from its points and check before the audit whether each one is met.

9. Learn from Best Practices in Various Industries and Countries

Pneumatic safety has been developing for decades in many industrial sectors. It’s worth learning from others’ experiences instead of solving every problem independently from scratch. Look for examples and best practices from the automotive, food, electronics, or other industries to inspire proven solutions.

Automotive example: In car factories, we find extensive pneumatic systems—lifts, manipulators, welding clamps, etc. This industry is known for stringent safety standards. For example, assembly lines often feature double cutoff valves with diagnostic systems to achieve PL e for emergency stop functions. If you design a machine with a similar risk level, see how automotive suppliers do it: they often publish case studies and recommendations.

Food/FMCG industry example: Packaging machines work quickly but must allow frequent operator interventions (e.g., clearing jams, cleaning). In such machines, a two-stage guard opening function is used: the first opening stops the machine but allows slow actuator movement (so-called jog mode) when holding a special button—only further opening fully cuts off air. This teaches us that safety systems can be flexibly designed to be both safe and not hinder work. In the food industry, much emphasis is also placed on simple LOTO procedures—e.g., cutoff valves are sectioned so that part of the machine can be stopped and serviced while the rest operates (if safe). This shortens downtime. Perhaps you can divide the system into zones with separate cutoff valves?

Electronics example: In electronics production, small actuators and grippers dominate, often in a clean environment. Here, pneumatic safety combines with reliability and precision—even a minor leak can halt a costly line. Companies in this industry invest in advanced pneumatic monitoring systems: flow and pressure sensors that detect deviations indicating seal wear or leaks. Although the main goal is production continuity, it has a safety aspect: it prevents failures that could result in uncontrolled movement (when a jammed actuator suddenly “catches on”). Learn from this that preventive maintenance and monitoring of the pneumatic system’s condition pay off. In your project, you can foresee additional diagnostic sensors—not required by the standard but can warn of a problem before it becomes a hazard.

International experience exchange: Standards like ISO 4414 are valid in many countries, but some regions also have their guidelines. For example, in the USA, besides ISO standards, ANSI standards and OSHA guidelines are used—there, much emphasis is placed on hose safety (e.g., tethers for securing high-pressure hoses) and warning labels. In Japan, machine manufacturers focus on miniaturizing safety components due to compact lines—many ideas for integrated safety valves combining several functions (cutoff + venting + soft-start in one) originated there. Follow industry literature, conferences, engineering forums—it’s a treasure trove of curiosities that can find application in your project.

Finally, don’t be afraid to ask more experienced colleagues or use consultations with component suppliers. Many pneumatics manufacturers offer technical advice on safety—they are eager to share examples from various industries because they also care about the correct and safe use of their products. An engineer learns throughout life, and safety is a field where it is clearly worth using the experiences of those who have already encountered and solved certain problems.

10. Document the Project and Train Personnel—Safety is a Continuous Process

The last but not least important tip goes slightly beyond the purely technical design of the system and concerns maintaining safety during operation. Even the best-designed pneumatic system according to PN-EN ISO 4414 can become dangerous if users are unaware of its operating principles or if modifications and repairs are carried out improperly. Therefore, already in the design phase, ensure solid documentation and prepare to train future users.

Complete technical documentation of the pneumatic system: It should include pneumatic diagrams detailing all elements (especially safety-related ones, such as cutoff valves, safety valves, sensors). Attach operation descriptions—step by step, explain how the system behaves in normal operation and emergency situations. For example, describe: “After pressing the safety mushroom, valves 1V1 and 1V2 cut off the air supply and open venting—cylinder X stops in a locked position thanks to check valves 1K1, 1K2.” Such documentation will be part of the machine’s operating manual required by law. It is essential that it is written in understandable language so that maintenance technicians and operators can learn from it. Avoid situations where only you as the designer understand how the safety system works.

Instructions and labeling on the machine: In the design, include space for safety plates and pictograms. For example, place information “Disconnect air here before work—risk of sudden start” near the cutoff valve. Stick green labels on gauges when pressure = 0 (safe), etc. Users do not look at diagrams daily, so visual markings on the device are key for proper use of safety functions.

Personnel training: As a designer, you may not always have influence over training at the client, but if you work within a company or deliver a machine, try to pass on knowledge. Explain to operators and maintenance personnel why a given safety measure is applied and how to use it. For example, show how to correctly apply a LOTO padlock, how to release pressure, how to recognize on the control panel an alarm that a safety valve did not work (if there is such diagnostics). When people understand the principle of operation, they are less likely to bypass or ignore it. Unfortunately, many accidents happen because someone deliberately disabled a safety measure—often out of ignorance of the consequences. Build a safety culture through education.

Modifications and maintenance: Design the system to be maintenance-friendly—i.e., use standardized components, ensure access to them, the ability to check the condition (filter wear indicators, cycle counter, etc., if required). In the documentation, indicate which elements are critical for safety and require original parts when replacing (e.g., “when replacing valve X, use an identical model or equivalent with safety parameters—do not replace with a regular 5/2 valve!”). Such guidelines will protect the service from unintentionally worsening the machine’s safety level.

Finally, remember that safety is a continuous process. Standards are subject to updates, technology evolves, and the way machines are used may change. Therefore, it is good to update your knowledge and periodically verify whether our machines still meet the requirements (e.g., with significant changes in the production line or after years of operation). PN-EN ISO 4414 provides a solid foundation—if you adhere to it and implement the above tips, your pneumatic projects will be not only functional but also prepared for safe, long-term operation.

Designing industrial pneumatics according to the PN-EN ISO 4414 standard requires considering a range of safety aspects—from risk analysis, through appropriate system architecture (redundancy, fail-safe), to attention to details like cutoff valves and documentation. The ten tips presented provide a practical guide for novice engineers: they help translate standard and regulatory requirements into specific design solutions. Let’s remember that at the center of these efforts is the human being—the operator, maintenance technician, and even a bystander near the machine. A well-designed pneumatic system ensures that the machine performs its tasks efficiently while not causing an accident even in unfavorable circumstances. This is what safety standards teach us, and we should always keep this in mind when designing subsequent industrial automation systems. Safety is an investment that always pays off. Good luck with your design!

FAQ: EN ISO 4414

No, but it recommends using the lowest possible working pressure that ensures proper machine operation.

It is helpful, but full compliance with essential requirements also involves meeting other standards, such as ISO 13849 and the Machinery Directive or the Machinery Regulation (often incorrectly referred to as the new Machinery Directive).

For example, safety valves, cutoff valves, pilot-operated check valves, and soft-start valves.

The word ‘LOTO’ (Lockout/Tagout) does not directly appear in the PN-EN ISO 4414 standard. The standard only requires safe disconnection and venting of the pneumatic system before maintenance or service work. These procedures are often implemented using ‘LOTO’ methods, which are standard in the industry, but the standard itself does not use this specific term.

Not always mandatory, but recommended in high-risk systems requiring a higher level of safety (according to ISO 13849).